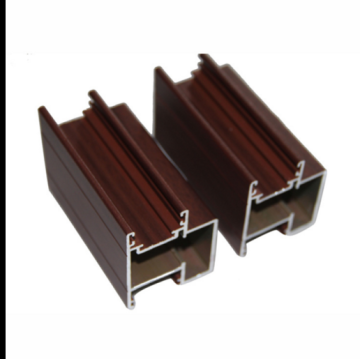

Wood Grain aluminum Profiles Building Decoration

| Unit Price: | 2800 USD |

|---|---|

| Min. Order: | 10 Ton |

| Productivity: | 3000tons |

|---|---|

| Brand: | HONG YING |

| Transportation: | Ocean,Air |

| Place of Origin: | china |

| Supply Ability: | 3000tons |

| Certificate: | ISO14001, ISO45001,ISO9001 |

| Port: | nansha ,shenzhen,guangzhou |

Basic Info

Model No.: 6000 Series

Product Description

6063 Wood Finish Aluminium Profiles Heat Transfer Wood Grain Profiles Building Decoration Aluminum Frame

| Product Name | 6063 Wood Finish Aluminium Profiles Heat Transfer Wood Grain Profiles Building Decoration Aluminum Frame |

| Implements Standard | GB5237.4-2008;ISO9001:2015;IS14001:2015 |

| Grade | 6000 Series |

| Thickness | 0.8-5.0mm |

| Temper | T3-T8 |

| Color | Wood,Brown,Red,White,Yellow,etc |

| Surface Treatment | Wood Grain,Anodized,Powder Coated,Electrophoresis,Polishing,Brushing,etc |

| Length | 6m or base on demand |

| Package | 1.protective film for each profile; 2.wrap with shrinking bag,pearl cotton or carton; 3.Packing according to customer request; |

| Load | Around 13tons For 20GP And 25tons For 40HQ |

Wood Grain Technology:

The wood grain transfer profile is based on the powder spraying or electrophoretic coating, according to the principle of high temperature sublimation thermal penetration, by heating and pressing, the wood pattern on the transfer paper or the transfer film is quickly transferred and penetrated to the profiles which have been sprayed or electrophoretic. The production of wood grain profile clear texture, strong sense of three-dimensional, better reflect the natural feeling of wood grain, is an ideal energy saving and environmental protection material instead of traditional wood.

Wood grain has strong adhesion to aluminum, which is non-toxic, odorless and easy to clean. Product lines clear and realistic, strong sense of three-dimensional, decorative effect is good, there is a return to nature, return to nature's visual effect. The coating on the surface of the aluminum profile can not volatilize or oxidize in the air without any pollution to the environment. The dirt deposited on the spray surface can be restored to its original luster and appearance after being washed.

Aluminum Extrusions Instead of Wood?

This aluminum stair rail has the appearance of wood.

Aluminum can serve as a replacement for wood in a variety of different projects. Doors, windows, cabinets, and building exteriors can all be given the appearance of wood.

So how do extrusion manufacturers create this pleasant wood effect on their aluminum profiles?

There are two processes, used consecutively, to create the look.

Powder Coating – One of the most common types of aluminum finishes.

Sublimation – Used to imprint patterns after powder coating.

After completing these processes you now have a replacement for wood that gives you all the benefits of aluminum extrusions.

Below we discuss these processes in more detail.

The 2 Processes Used to Create the Wood Effect

As mentioned above, manufacturers put extrusions through two consecutive processes to create the wood texture – powder coating and sublimation.

The First Process: Powder Coating

Aluminum receiving a base coat before curing.

Aluminum receiving a base coat before curing.

The powder coating process can be divided into three steps:

Base Coat – Manufacturers apply a base coat of powder to the aluminum extrusions. The powder is electrostatically charged to enhance adhesion.

Curing – The profiles are placed in a curing oven. Typically they’re kept in the oven for about 10 minutes, at temperatures of around 200 degrees Celsius.

Cool Down – The profiles are removed from the curing oven and allowed to cool down. Once they’re fully cooled, it’s time for the sublimation process.

The Second Process: Sublimation

The sublimation process has four primary steps:

Film Wrapping – A film with the decorative pattern (In this case, wood grain) is wrapped around the aluminum profile.

Air Removal – All air is removed from the space between the film and the profile. This way the film stays firm against the coated aluminum.

Curing – Wrapped extrusions are placed into a curing oven. As they heat up, the wood grain pattern gets transferred from the film to the aluminum.

Cool Down – Extrusions are pulled out of the oven and the film is removed. At this point, the pattern has been fully transferred onto the aluminum profiles. They are allowed to cool down.

After powder coating and sublimation, the extrusions can now be shipped.

Incorporating Aluminum Extrusions into Your Project

Aluminum extrusions can be designed as complex interlocking shapes. The wood effect gives them a nice, natural look. Now you can design products that have a nice, natural look and all the benefits of aluminum.

At Gabrian, we provide custom aluminum extrusion and finishing services through our partners based in India.

If you are considering wood-look extrusions, it is most cost-effective to have the profiles extruded locally in India and then finished at our finishing partner, which is also in India.

We can provide a comprehensive quote for extruding, finishing, and any minor assembly operations. The wood-look finish comes with a 10-year guarantee for external applications.

Wood Pattern Options

View our catalog of wood pattern options for your custom extruded aluminum profiles.

30 different patterns to choose from.

Advantages of Aluminum Extrusion:

Aluminum is a very commonly specified material for use in extrusions and shape profiles because it possesses mechanical characteristics that make it ideally suited for the shaping and forming metal from billet sections. The high malleability of aluminum means that the metal can be readily shaped into a variety of sections without expending significant energy on the tooling or forming process, and the melting point of aluminum is also generally on the order of half that of ordinary steel. Both of these facts mean that the aluminum extrusion process has a relatively low energy footprint translating into low tooling and manufacturing costs. Finally, aluminum also possesses a high strength to weight ratio, making it an excellent choice for industrial applications.

Types of Profiles:

A wide variety of intricate aluminum extrusion profile types can be created at varying thicknesses. These profiles can feature a wide variety of intricate void spaces, as necessitated by the end use application. A wide range of internal voids are available in order to facilitate a wide variety of automation applications and also satisfy any performance weight requirements. The most common type of aluminum profile is the hollow beam profile which is simply a variation of the square profile. There are also other profile types such as the triangular, single radius, and L-shaped profile.

Yonglong aluminum extrusion profiles. Visit www.aluminumwindowprofiles.com for a full selection of available profiles, lengths, and surface treatments.

Surface Types:

As a byproduct of the extrusion process, there are sometimes small, barely visible lines present on the surfaces of the profiles. This is a result of the extrusion tooling, and additional surface treatments can be specified to remove these lines. There are a few of secondary surface processing operations that can be performed such as face milling after the main extrusion forming process in order to improve the surface finish of the profile section. These processing operations can be specified in order to improve the geometry of the surface to improve the part profile by reducing the overall surface roughness of the extruded profile. These treatments are typically specified in applications that require precise positioning of the parts or where mating surfaces must be controlled tightly. Surface treatments can also add additional corrosion resistance, improve the hardness of the profile, or even add electrical insulation to the extrusions.

Corporate Introduction:

Guangdong Yong long Aluminum Co., Ltd. is located in the No. 10 (Sanjiang market) of Leping Town, Sanshui District, Foshan. The company was founded in 1997. It is a comprehensive and large-scale aluminum profile enterprise integrating the research and development, production and sales of aluminum alloy profiles. The company is leading the "Hong Ying" brand. Strong comprehensive strength and excellent service make Yong long "Hong Ying" sell well all over the country and exported to Southeast Asia, Europe, South America and many other countries.

Our company has 900 employees, including 120 high and intermediate engineering technology and management personnel, with advanced and perfect design, production, testing and testing methods as well as perfect sales network and after-sales service system. The products sell well in more than 10 national and foreign ports, Australia and Taiwan areas.

Corporate Advantages:

1.20 years' experience and advanced equipment

2.Customize: We can manufacture according to your size and shape of such aluminum profile;

3.Strong production capacity - 28 extrusion lines, 50,000TONS/Year

4.One Stop Service Specialized in mould, extrusion, anodizing, powder coating, wood grain and Processing;

5.Shortest Delivery , competitive prices and excellent service

Corporate Certification:

After years of development, the company passed the ISO9001: 2000 quality system certification, the international standard product certification. Yonglong Aluminum has won the "Guangdong Province Famous Brand", "Guangdong Province Famous Brand", "ISO14001 Environmental Management System Certification", "OHSMS18001 Occupational Health and Safety Management System Certification", "Adopting International Standard Products" Is "," China's quality products "and other certificates. Companies adhere to the scientific concept of development, by strengthening the comprehensive management and increase innovation, and continuously enhance the energy-saving emission reduction enterprises to accelerate into the environment-friendly modern enterprise list.

Corporate Culture:

The company insisted: "unity and progress, pioneering and innovative, high quality of this, service to win" business purposes, the new full cooperation with customers, Gongtuo career, create a better future.

When you work with us, you can expect top-quality resources and parts, excellent customer service, and to be treated like family. We’re invested in this industry and our clients. When you work with us, you can tell the difference!

We welcome customers from all around the world!

Sublimation Process – How to Make Aluminum Looks Like Wood So how to make aluminum that looks like wood? There are mainly two methods for making aluminum that looks like wood: SUBLIMATION PROCESS (famous as Decoral), and POWDER ON POWDER PROCESS(famous as Naturall). SUBLIMATION PROCESS to get a wood finish on aluminum is the most commonly used technology for the aluminum industry in China. YONGLONG ALUMINIUM, as a professional aluminum extrusion manufacturer, with both woodgrain sublimation production lines and powder coating production lines, would like to introduce how to make aluminum that looks like wood through the sublimation process. At present, most of the wood grain sublimation process is: aluminum pretreatment ; base-color powder coating & curing ; wood grain transfer paper covering ; curing ; paper removal. Heat Transfer Process: Wood grain transfer profile refers to the transfer of the wood grain pattern on the printing paper or transfer film by heating and pressurizing on the basis of powder spraying or electrophoretic coating, according to the principle of high temperature sublimation heat penetration Penetrate into the profile that has been sprayed or electrophoresed. The wood grain profile produced has clear texture and strong three-dimensional effect, and can better reflect the natural feeling of wood grain. It is an ideal energy-saving and environmentally friendly material to replace traditional wood. Please tell us the information below, and we will give the best suggestion to you ! 1. Where you intend to use the aluminium profiles? 2. If you have the estrusion drawing, send us and we develop the correspondence mold. 3. Which color you want or tell us the architectural style you like. 4. Purchase quantity. It will convenient us to give you the best price.

Ceilings, cladding, curtain walls, and partitions with aluminum wood finish are often seen in commercial buildings. In the home interior decoration, wood-like aluminum doors and windows are prevalent now, and aluminum furniture cabinets with wood grain color has begun into the market. Now you can see many wood colors in garden design, like fencing and gates, decking, house siding, railing. Comparing with the surface of RAL color, the wood finish is more lively, atmospheric, and close to nature.

Wood grain has strong adhesion to aluminum, non-toxic, odorless and easy to clean. The product lines are clear and lifelike, the three-dimensional effect is strong, the appearance decoration effect is good, and the visual effect of returning to nature and returning to nature. The coating film on the surface of the sprayed aluminum profile is non-volatile and non-oxidized in the air and does not pollute the environment. The dirt deposited on the sprayed surface can be restored to its original luster and appearance once it is cleaned.

Process 1: Suitable for large area or special-shaped substrate

Suitable for large area or special-shaped substrate

The first step: select the substrate that has been sprayed or electrophoresed

Step 2: Wrap the substrate to be transferred with wood grain heat transfer paper, and fix the paper interface with high temperature resistant adhesive paper to prevent the wood grain heat transfer paper from loosening. (Note: The front side of the wood grain heat transfer paper should be pasted to the surface of the substrate to be transferred.)

Step 3: Put a high-temperature resistant and well-sealed tubular plastic plastic bag on the substrate that has been wrapped by wood-grain heat transfer paper, and then draw a vacuum from both ends of the plastic plastic bag until the plastic plastic bag can Adhere to the substrate fully and effectively.

The negative pressure of the vacuum should be adjusted appropriately according to the characteristics of the substrate to be transferred and the negative pressure that the plastic plastic bag can withstand, usually between 0.3 and 0.8Mpa. (Note: The purpose of using plastic bags is to force the wood grain thermal transfer paper to fully and effectively adhere to the substrate through negative pressure.)

Step 4: Send the wrapped substrate to the oven for baking. The baking temperature and time should be based on the characteristics of the substrate to be transferred, the depth of the texture to be transferred, and the specific performance of the oven. Make appropriate adjustments, usually the transfer temperature is 160~180℃, and the time is 5~8 minutes

Step 5: Take out the transferred substrate from the oven, pull off the plastic plastic bag from one end of the transferred substrate (note: this plastic plastic bag can be reused), tear off the heat transfer paper, Do surface cleaning

Process 2: Suitable for flat substrate

Suitable for flat substrates

The first step: select the substrate that has been sprayed or electrophoresed

Step 2: Lay the front side of the wood grain heat transfer paper opposite to the front side of the substrate to be transferred

The third step: press and heat the flat heat transfer machine, usually the temperature of the transfer is 160~180℃, and the time is 18~25 seconds

Step 4: Tear off the heat transfer paper and transfer with PET heat transfer film

Process 3: Suitable for special-shaped substrates

The first step: select the substrate that has been sprayed or electrophoresed

The second step: Wrap the transferred substrate with PET heat transfer film, and seal the PET heat transfer film into a tubular bag with an ultrasonic sealing machine. (Note: The front side of the PET heat transfer film should be attached to the surface of the substrate to be transferred.)

The third step: Vacuum from both ends of the tubular PET heat transfer film bag until the PET heat transfer film can fully and effectively adhere to the substrate. The negative pressure of the vacuum should be adjusted appropriately according to the characteristics of the substrate to be transferred and the negative pressure that the PET heat transfer film can withstand, usually between 0.3 and 0.8Mpa

Step 4: Send the wrapped substrate to an oven for baking. The baking temperature and time should be based on the characteristics of the substrate to be transferred, the depth of the texture to be transferred, and the specific performance of the oven. Make appropriate adjustments, usually the transfer temperature is 160~180℃, and the time is 5~8 minutes

Step 5: Take out the transferred substrate from the oven, and remove the PET thermal transfer film by manual or mechanical blowing (that is, blow the PET thermal transfer film tubular bag by blowing).

Product Categories : Aluminum Profiles > Construction Aluminum Profiles